| Special award |

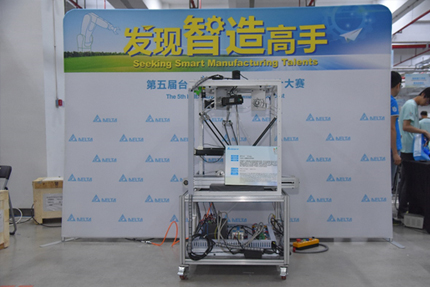

|

| School Name: |

Xiamen University |

| Team: |

Gemini |

| Project: |

Delta Gemini |

| Introduction: |

Delta Gemini apply the high -speed Parallel Manipulator with machine vision to sorting objects, which can be divided into two parts: Picker Pollux and Master Castor. Picker can find the object to be picked by template matching based on shape model. After getting the coordinates and degrees, the system convert these data to the controller, letting the parallel manipulator grab the object accurately. So the Picker can complete the task of quick sorting and piling with a high accuracy. Besides, Master Castor, a virtual simulation environment, is powered by Unity 3D. And the system can do a lot, including clone the real movement, virtual simulation, performance evaluation and virtual dismounting. These practical functions can boost the working efficiency and bring a great convenience to the users.

In a word, the two parts (Picker and Master) can cooperate perfectly and achieve the real “Intelligent Manufacturing”.

|

|

|

|

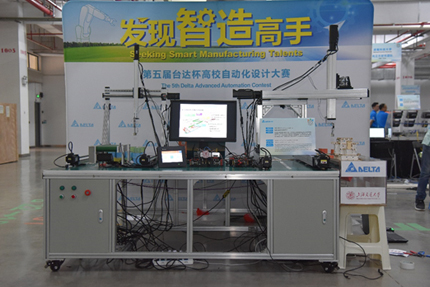

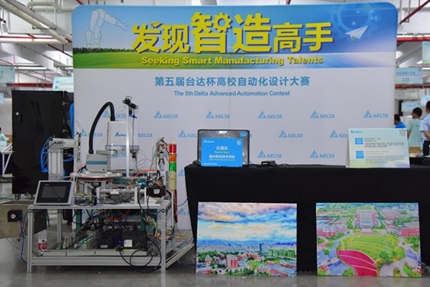

| School Name: |

Shanghai Jiao Tong University |

| Team: |

Magic Control |

| Project: |

Intelligent Container Terminal Logistics System |

| Introduction: |

| The intelligent container terminal logistics system is designed to simulate and optimizes the transport process of a terminal. This system includes three collaborative optimization control units: AGV, terminal gantry crane and terminal bridge crane. In this system, we use IoT and cloud platform technology to develop an intelligent optimal scheduling strategy, which can significantly increase the container transport efficiency, reduce the storage and labor costs and lower the accident rate caused by human factors.

|

|

| |

| First prize |

|

| School Name: |

Vellore Institute of Technology |

| Team: |

Alfred & Cadbury |

| Project: |

Smart Logistics Solution – Warehouse BOT Scheduling with Swarm Robotics and Machine Learning |

| Introduction: |

This logistics solution uses mechanical bots for automatic product retrieval according to orders. This solution features machine learning (clustering) as core function to configure the work region of dynamic allocation and save operation time, and adopts three transportation bots (a master and two slave) for goods collection/retrieval.

The master transportation bot, followed by one of the slave bot, moves along the shelves to fetch the goods and put them on the slave transportation bot. When the slave bot is fully loaded, it will take the goods to unloading area while the other empty slave bot taking over and following the master bot for constant goods collection. The swarm robotic operation optimizes logistics efficiency with non-stop, unlimited, flexible collaboration.

|

|

|

|

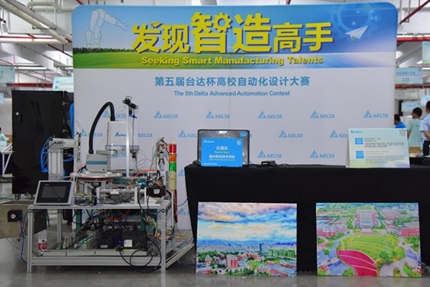

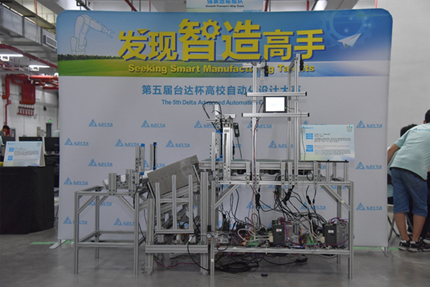

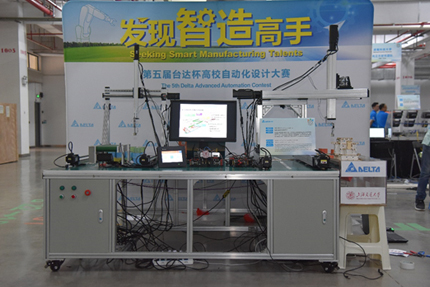

| School Name: |

Nanjing Institute of Technology |

| Team: |

Leaping Power |

| Project: |

Visual Autonomous Learning Robot that Cooperated with High Speed Sorting System Design |

| Introduction: |

| We use Delta’s SCARA Industrial Robot and Delta’s Machine Vision System as the main equipment to design an independent high-speed sorting system for industrial production. It achieves the automatic recognition of the colors and positions of objects which are circles, polygons and so on. Afterwards, it completes the different objects under different circumstances. The topic of the project will be combined with productive practice and we will carry on the idea innovation. The technological breakthrough of machine vision is the key link in the development of robots. The project will combine machine vision with multi-robot collaborative work, and introduce artificial intelligence algorithms for autonomous learning. Designing a high-speed sorting system with self-adaptive function has practical value of production and use.

|

|

| |

|

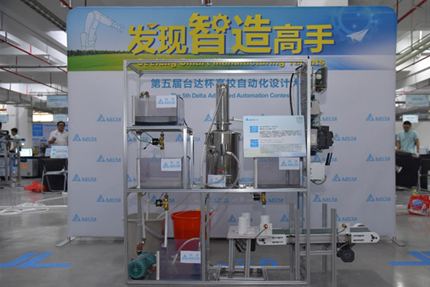

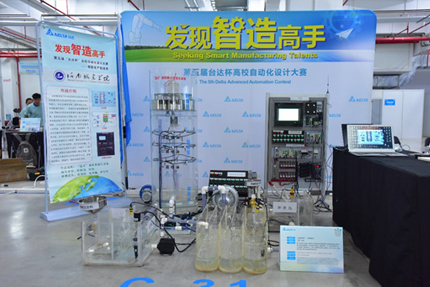

| School Name: |

lishui vocational and technical |

| Team: |

rocket |

| Project: |

Automatic organic fertillizer production |

| Introduction: |

| The construction of this project system adopts the equipment of daida, and the industrial Ethernet technology of daida connects the various stations To form an intelligent manufacturing system, and integrate with the mobile APP software, to realize the system remote monitoring Vision, data collection and management.

|

|

|

|

| School Name: |

Nanjing Xiaozhuang University |

| Team: |

Giant of Wisdom |

| Project: |

Intelligent beverage service all-in-one machine |

| Introduction: |

| On the one hand, users can choose different concentrations of coffee or milk tea according to their preference. They can make purchases through the phone app or touch screen of the machine. After user's opreation, an empty cup will fall out of the machine and then complete a series of steps for coffee packaging, which truly realized bilateral private customization. In the future,we will add storage lattices inside the machine, and the user will open the cabinet door to extract the drink through the QR code or short message verification code .On the other hand,the machine also supplies free water at different temperatures to users as long as they take their cups. It's of great benefit to users, which is contribute to the creation of a harmonious social atmosphere . At the same time, in this way, we don't have to put the water dispenser anymore, it can help us save a lot of space. It can be said that kill two birds with one stone . |

|

| |

|

| School Name: |

JIAMUSI UNIVERSITY |

| Team: |

Stars of the East China pole |

| Project: |

Intelligent control system of straw baling machine |

| Introduction: |

1.We first introduce Delta products in the field of agriculture machinery, which is a potentially huge market. This measure will exploit new markets for Delta.

2.It can collect and convey the operational data by monitoring equipment in the machine to ensure precise monitoring of machine operation status and data. This move will provide a quantitative basis for machine's supervision and raise the level of agriculture machinery management informatization.

3.It can interact with tractor drive through voice broadcast, which lower threshold of the agriculture apparatus.

4.The system can make intelligent diagnosis on the equipment. This measure makes equipment maintenance easier to operate.

|

|

|

|

| School Name: |

National Formosa University |

| Team: |

Light^3 |

| Project: |

Automated Production Line with a Remote Controlled Multifunction Robotic arm |

| Introduction: |

| This solution for smart factory is built with automated equipment and techniques. It utilizes a self-developed automatic equipment to create a cross-field integrated multi-functional factory. Firstly, users can initiate a project by creating and editing on the Web page or an APP ; after that, they can opt for combining different projects to remotely operate the production line. This solution not only uses the surveillance system to get information of hardware status in real-time, but also provides accurate and stable program control.

|

|

| |

|

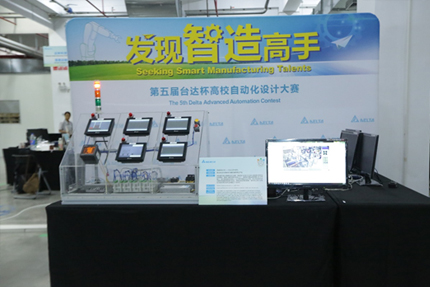

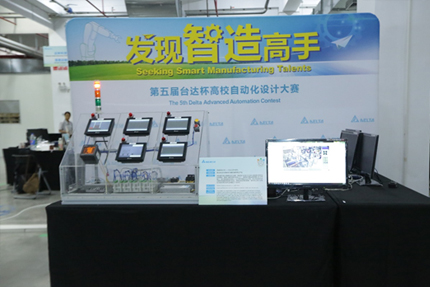

| School Name: |

National Yunlin University of Science And Technology |

| Team: |

Assault Transport Ship |

| Project: |

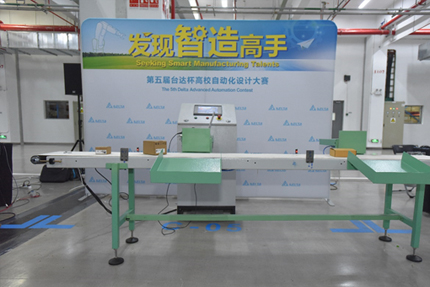

Mini Classified Conveyor |

| Introduction: |

| This solution utilizes Delta Machine Vision Systems to identify the QR code on the boxes; it can automatically determine types of goods on the conveyor, and send them to the different delivery lane. This flexible, automated logistic sorting solution can handle multiple orders in one single production line. |

|

|

|

| School Name: |

Vellore Institute of Technology |

| Team: |

MATRIX 2.0 |

| Project: |

E-retail Order Sorting and Verification System with IIoT |

| Introduction: |

Based on the concept of Industry 4.0 and Smart Machines, our team proposes an Automated Product Sorting and Validation System for retail products, meeting the needs for E-commerce industry. The features include:

2 solid databases for efficient management: The primary database manages the warehouse inventory, while the dynamic one maintains information about the products to be shipped on a particular date and time to the respective customers.

Fast and precise inspection and sorting system: Using an overhead machine vision system to identify and compare the products arriving for packing based on the data from primary and dynamic databases. Then a multi-conveyor sorting system will sort the verified products according to their shipping hubs. If a product is not in the dynamic database, a feedback system will send it back and discards the ones that are unidentified in both databases.

Real-time tracking for customers: An industrial PC will track the shipping process and send updates to the customers through IIoT

|

|

| |

|

| School Name: |

Chulalongkorn University |

| Team: |

CU Soon |

| Project: |

Automatic DIY Fruit Frappe Vending Machine |

| Introduction: |

This solution is a smart DIY fruit frappe demo machine. The water of 3 different colors in the 3 tanks represents 3 types of fruits, and the machine can adjust the volume of each kind inserted into the cup to make customized “fruit frappe”.

The machine also implants a face recognition system that can detect and recognize customers to identify their orders and their favorite drinks. In addition, it has an alarm system; when cups or water is nearly out of stock, it will send out an alarm message to the manager for restock. Finally, the machine supports QR code payment for customer’s convenience.

|

|

|

|

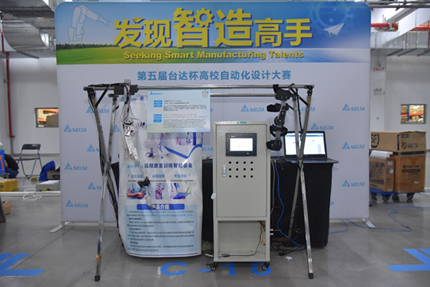

| School Name: |

Chengdu University of Information Technology |

| Team: |

Eggshell |

| Project: |

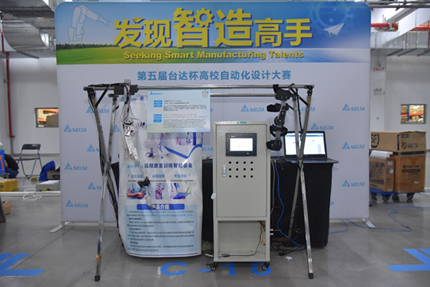

the Intelligent equipment of remote rehabilitation training for elderly stroke patients |

| Introduction: |

| This is a set of wearable intelligent equipment, including the intelligent rehabilitation device, cloud platform, rehabilitation training WEB. 3 functions, such as, autonomous training, multiple mode switching, remote guidance rehabilitation functions are endowed in the set of wearable intelligent equipment. It is used to reconstruct the patients' central nervous system to control the affected limbs, to adjust the muscle tension, to exercise the muscle strength and to coordinate the movement, so as to restore the normal movement function of the patients, and a new experience of rehabilitation training for the patients will be realized. |

|

| |

|

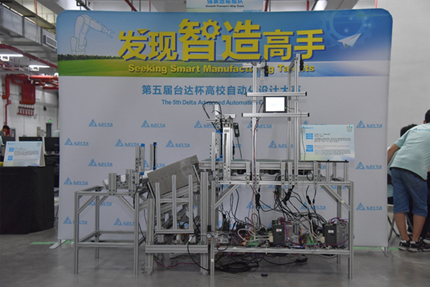

| School Name: |

nanjing institute of industry technology |

| Team: |

Rhyme team |

| Project: |

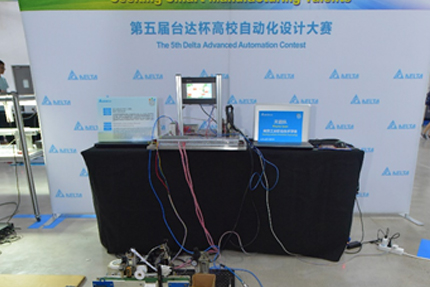

Optimal control of intelligent production line |

| Introduction: |

| This scheme is mainly aimed at intelligent production. Make full use of the delta cloud platform, carry out real-time detection and data sharing on all the data on the factory line, and adjust the production through the data analysis of the purchasing end and the forecast demand and sales management, and realize the information interaction between the planning layer and the control layer, thus reaching the product from the order to the product. The whole production process is optimized to manage, make full use of the Internet platform resources, better realize the client, the cooperation of processing and production, low cost, efficient and efficient processing system for manufacturing industry, reduce the cost, improve the income, eliminate the abnormal, and improve the productivity. |

|

|

|

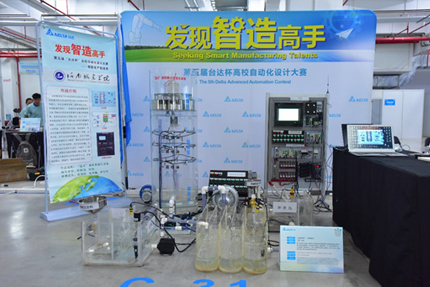

| School Name: |

Harbin HuaDe University |

| Team: |

A leap dream |

| Project: |

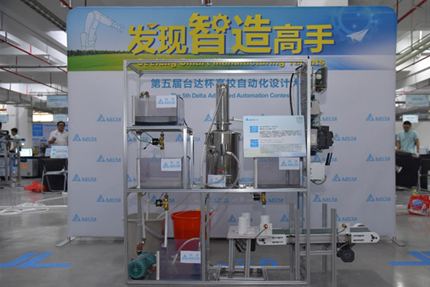

Solution of intelligent seawater desalination |

| Introduction: |

| This system takes PLC as the core and adopts network control technology, which can simplify the design and satisfy the needs of automatic control. The pretreatment of seawater is cleaned up in advance. The distillation and condensation method is used to desalination the sea water. The process is simple and easy to be realized, and it will not be restricted by the salt content in the water. And it can make full use of the waste heat project, desalination the purity of the sea water and reach the standard for drinking. Standardization, modularization, systematization and Mechatronics design are adopted to make the system more flexible, intelligent and fully automated. |

|

| |

|

| School Name: |

Henan University of Urban Construction |

| Team: |

Mohism of Eagle City |

| Project: |

”blue sky”desulfurization |

| Introduction: |

| The first domestic use of double alkali method + electrostatic dust intelligent equipment and wet electrostatic dust eliminator desulfurization equipment and with a wireless remote control system, to avoid scaling inside the tower, high desulfurization efficiency, no secondary pollution can be recycled, the system long-term Features such as stable operation. At the same time, it can realize automatic control and on-line monitoring, reduce enterprise losses, reduce operational risks and have the advantage of effectively improving the environment.

|

|

|

|

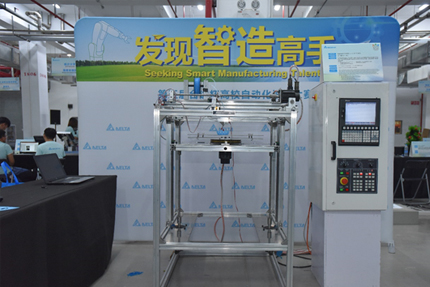

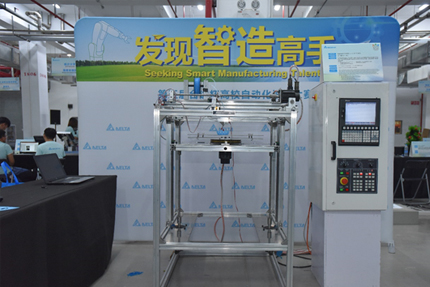

| School Name: |

R.V. College of Engineering |

| Team: |

Clone Tribe |

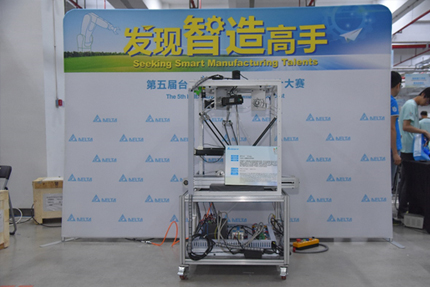

| Project: |

Smart 3D Scan-to-Print Machine |

| Introduction: |

| This 3D scanning & printing solution is designed with the additive manufacturing concept. It utilizes laser displacement sensors for the scanning process, and can easily complete the scanning of objects within maximum outer diameter 600mm and height 700mm. It also features user-friendly interfaces and easy maintenance, and can be applied to any offices without requiring special expertise or dedicated personnel. The printer frame is made of aluminium T-slot, and adopts biodegradable material, PLA (poly lactic acid) of diameter 0.75mm, for printing to achieve good 3D printing quality and eco-friendliness.

|

|